Transmission Type: Flexible Certification: ISO, CE, LR, ABS Flexible Production: Intelligent Manufacturing Production Scope: Product Line Voltage: 380/415 Warranty: 1 Year Capacity: 20000-100000 Cbm/Year Weight: 500 T Delivery Detail: Shipped in 70 Days After Payment Specification: At least 2000 square meter HS Code: 84659100 Automatic Production Line: Comprehensive Automation: Automation Rhythm: Non Flow Production Line Condition: New Power: 3000kw After-Sales Service Provided: Engineers Available to Service Machinery Overseas The Thickness of The Board: 3-50 mm Raw Material: Wood-Based Trademark: XINLIHUI Origin: Shandong, China (Mainland) 1,

MDF Production Line/ Medium Density Fiberboard Production Line

Our main products are Particle board production line,

Plywood production line, MDF production line, Melamine veneer press,Mould door equipment etc. based on our good quality as well as perfect service ,our business scope expands extensively both at home and in more than 20 countries such as Vietnam, Malaysia, Pakistan ,Bangladesh, Russia, Turkey and so on. And they are all well praised by our clients.

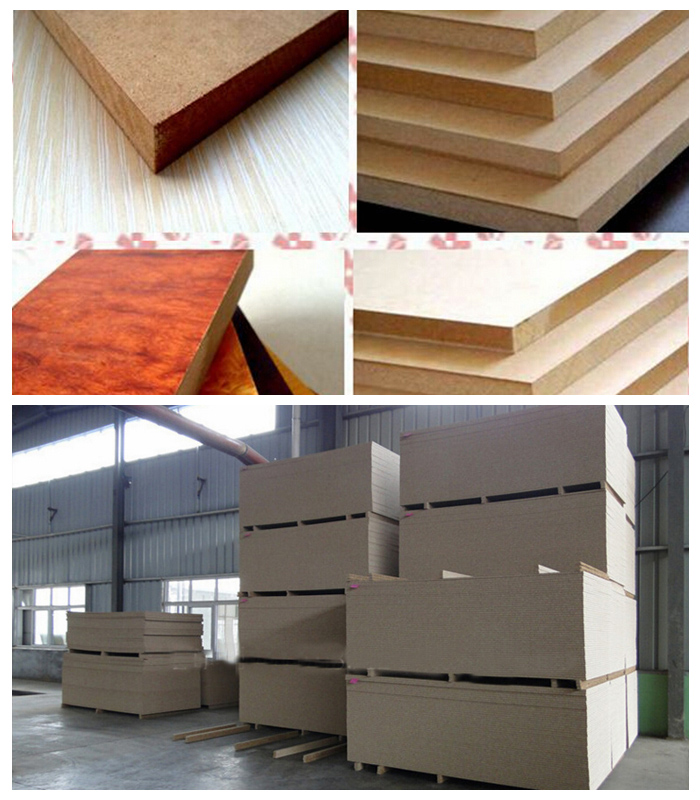

MDF/HDF is a kind of excellent substitute for natural wood panel with wide application. Materials such as wood and other plant fiber after being added suitable urea formaldehyde resin or other adhesives forms 650-880 kg/m3 panels on hot press. The panels are characterized with tight and smooth surface, uniform core layer and good wood working performance.

1) All kinds of mold can be made by customer's drawings

2) All price are based on FOB, QINGDAO, China

3) Payment: by T/T 30% down payment, 70% upon machinery completion.

4) Delivery: After finishing all the payment

5) All the parameters above just for reference, for they are updating all the time

6) Package: Standard packing

7) Warranty: All the machine enjoys one year's warranty, in this period.

2,Product Description Main Technical Data of MDF production line

| MDF Production Line |

| Voltage | 380v/ 415v |

| Capacity | 30,000~60,000 cbm |

| Board Size | 4*8 (1220*2400) |

| Raw Material | Wood Branch, log, waste wood, sawdust and left overs |

| Control Method | PLC, CNC |

The line consists of material preparation section, fiber preparation section, glue mixing and applying section, forming and hot-pressing section, cooling and trimming section, sanding section. 1. Material preparation section The raw material is reduced into sized wood chip by chipper. Then the wood chip is conveyed by belt conveyer into a chip silo for temporary storing. Wood chip feed out from the chip silo, passing through swinging screen to remove small particles, mud and sand, then transported into pre-heat silo of refiner by a bucket conveyor. 2. Fiber preparation section Wood chip in pre-heat silo is pre-heated by saturate steam, then evenly entering digester via screw feeder to cook and soften the chips, so fiber is easy to be separated. The cooked wood chip is reduced into fiber by the function of heat and mechanical movement. Then the reduced fiber is transported to dryer or cyclone by blow valve via fiber-spray-tube. Glue jetting device is set on the fiber-spray-tube. Paraffin wax adding hole is set on the defiberator-housing, it can feedback glue applying volume according to the chip volume in the refiner. Fiber mixed with hot drying medium, is suspended in such a high-pressure and high-speed air-flow that water staying in the fiber is evaporated by the drying medium in the dryer. Then through the lower discharging-opening of cyclone, the fiber falls onto the forward-reverse belt conveyer and transported to dried-fiber-silo for temporary storage. Spark detector is set on the drying pipe for fire extinguishing system. 3. Glue regulating and applying section Our technique is glue applying before drying. Melt paraffin wax and other waterproof-agent are sent to the refiner, mixed evenly with the fiber by grinding and squeezing of grinding plates. Glue jets into the fiber-spray-tube under a certain pressure via pipes. The glue mist adheres to the surface of fiber by the high-speed air-flow in the pipe. 4. Forming and hot-pressing section This section including forming, pre-pressing, mat conveying, mat cutting, hot-pressing, cooling and trimming, to produce quality board. Dried fiber is transported at a certain speed to the upper part of forming machine (the spreader/former), then spread evenly onto annular screen-belt conveyer by spike-rolls. There is vacuum box under the screen-belt, air is sucked through the screen-belt and fiber is adhered on the screen-belt, thus forming a loose mat. Pressed by the pre-press, the loose mat is reduced into a relatively density mat, then cut into sized mat by mat-transversal-and-longitudinal saw. Transported by synchronous conveyer, acceleration belt conveyer, and fast-speed belt conveyer, the mat is carried to board loader. The cauless belt-trolley of the loader transports the mats into hot press, meanwhile, the pressed rough board is pushed out. When the cauless belt-trolley of the loader reaching its terminal point, the pressed rough board enters unloader completely, at the same time, mat reaches its position in hot-press. The mat stays on the press-platen of a hot press, then it is pressed into a certain thickness by the hot press. Meanwhile, the inner adhesive is hardened, thus a piece of fiberboard (rough board) with certain strength is produced. After pressing, the fiberboard is transported to the next section. 5. Cooling and trimming section The board after hot pressing, passing a board-turning-cooling machine, inclined roller-conveyer, then entering transversal-longitudinal saw, is cut into size medium density fiberboard, stacking for short storing. 6. Sanding Section The rough board is transported by forklift truck, and placed on h ydraulic lift. Pusher pushes board into feed-roller, sanding by wide-belt sander. Hardened surface is removed, and obtain required thickness and roughness. After checking, rating, stacking, packing, finally, the board is sent into ware-house for storage. 3, Details of the production line

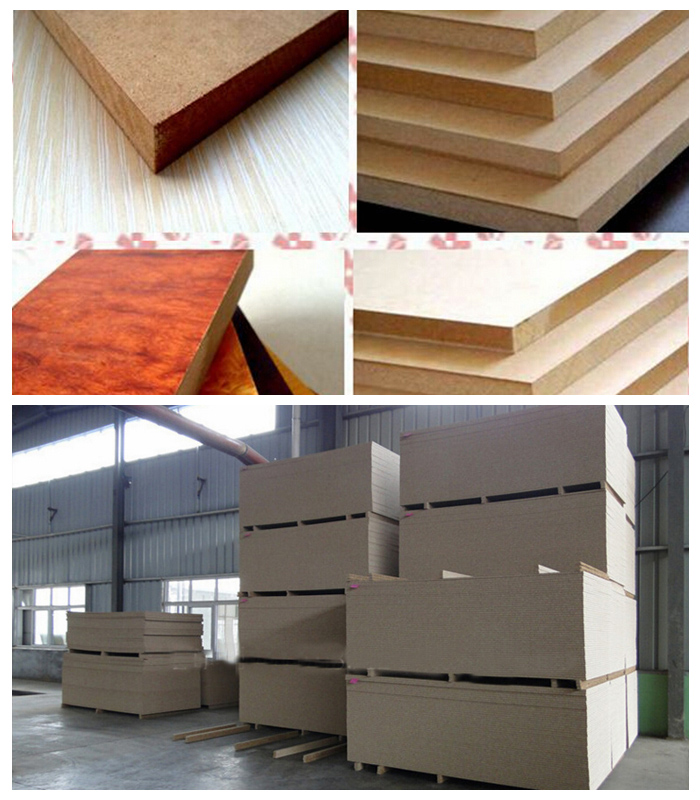

4,Finished products

5,Here we promise these :

1:One stop service for all kinds of woodworking machines for you

2, high cost performance with reasonable price and our best quality

3:15-20 days delivery time

4:Excellent after-sale services

5:24 hours technical support through email or calls.

6:Not only business, hope to make good friend with you

For further information about machine or price or other service , plz contact with us by email or QQ or wechat

Your enquiry are always warmly welcomed

Contact us if you need more details on MDF Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Medium Density Fiberboard Production Line、HDF/MDF/

Ldf Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Wood production line > MDF Production Line