Product Description Product Application High Speed Short Cycle Woodworking Hot Press Machine

The short cycle press line is for laminating melamine paper / phenolic film / veneer on particle board / MDF / HDF / plywood. The laminates could have all kinds of surface texture such as glossy, mirror, matt, suede, snow, woodgrain, and EIR board.Surface material: Melamine paper, Phenolic film, Veneer

Core board: MDF, HDF, Particle Board, Plywood

| Model | Size( ft ) | Nominal pressure (KN) | End panel size(mm) |

| YX1200 | 4x8 | 12000 | 1220 x 2440 |

| YX1400 | 4x8 | 14000 | 1220 x 2440 |

| | 4x8 | 16000 | 1220 x 2440 |

| 6x8 | 16000 | 1830 x 2440 |

| 6x9 | 16000 | 1830 x 2750 |

| YX2000 | 7x9 | 16000 | 2100 x 2750 |

Main Features 1. Aging treatment: The steel used in our lamination machine was after aging treatment, that's make our material more uniform stress. High Speed Short Cycle Woodworking Hot Press Machine

2. Frame mechanism: The closed frame is strengthened, which will ensure its working accuracy by appropriate design, reinforced mechanical properties and machining each surface.

3. Oil cylinder adopts the advanced sealing technology, cast-steel cylinder body, chill-iron plunger and good machining accuracy, all of which will extend the working life of cylinder.

4. Synchronous mechanism: The synchronization mechanism have also been improved. The synchronization result is more smoothly.

5. Hydraulic pump station: The using of a new type of hydraulic pump station revolutionary changes our hydraulic oil cooling method.

7.The process of communication between equipment and man are all disposed by the PLC controls ,all helping to achieve high reliability and flexibility of production, the PLC controls and main electronic components are from international brand.

Company Infomation

Wuxi Qiangtong Machine Factory has built a solid reputation over 12 years of groundwork and over 150 units if QT lines are using by our honored customers from Iran, Turkey, Canada,Mexico, Venezuela,India, Egypt, Uzbekistan, Kazakhstan.,etc.

We are a prominent Chinese manufacturer that specializes in the development, production, and distribution of

Wood Based Panel Machinery. Our most popular products consist of the semi auto & fully auto

Short Cycle Hot Press Line, the

Paper Impregnation Line,

PUR Hot Melt Glue Press Line and UV glossy coating line.

Detailed Images

Machine Parts Name: Belt conveyor loader The belt conveyor loader is used for sending the paper together with the raw board automatically.

It has two steps speed, first fast then slowdown in the end. The fast speed to short the loading time, higher the work efficiency. The slow speed is for ensure the position accuracy.

Main Features Name: Main hot press machine

The frame of press is manufactured from high quality plain steel plate and stress analysis and computation in detail to ensure the enough stiffness and safety factor.

The cylinder with high intensity is made of cast-steel. The cylinder plunger is made of hard iron and is wear-resisting. Its surface hardness is high that can reach above HRC55.

The

Hot Platen is made of a whole massive steel plate and the heat pipes distributed in it reasonably to ensure its working surface temperature is uniform.

Machine Parts Name: Vacuum pad unloader The vacuum pad unloader is for unloading the laminated board by vacuum pad instead of pushing by hand.

The speed is adjustable by the inverter controller, so you could modify the speed according to your production capacity.

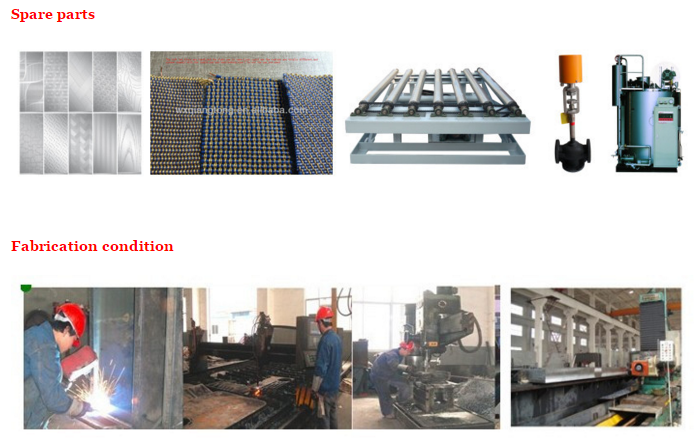

Roller table

Electrical cabinet

Hydraulic station

Our Service Pre-Sales Service 1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

4> Welcome to visit our factory

After-Sales Service 1> Inspect the machine before leaving the factory.

2> Oversea install and debug the equipment

Payment Term By T/T, 30% deposit, 70% paid before delivery. We have Kunlun Bank especially for Iranian payment.

Necessary spare parts

| Commodity | Specifications | Qty. |

| | 4x8 feet, 1460x2660x5 mm | 2 pcs |

| One side chrome surface, 633 SS material | |

| Glossy or matt design. | |

| | 4x8 feet, 1470x2800 mm | 2 pcs |

Temperature control system | Solution 1: | 2 pcs |

| Single temperature control valve; | |

| Honeywell brand, for controlling hot oil temperature. | |

| Solution 2: | 2 sets |

| Second recycling system; | |

| It's a recycling system consist of Honeywell temperature valve and pump with circuit. | |

Packing & Delivery

Some parts in wooden case, some parts without package, which are all suitable for ocean transport. Related Products

Laminate floor hot press 91.8% Response Rate Multi layers door skin hot press 91.8% Response Rate Automatic laminate hot press line 91.8% Response Rate

Contact us if you need more details on Woodworking Hot Press Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cycle Woodworking Hot Press Machine、Short Cycle Woodworking Hot Press Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Short Cycle Hot Press Line > Melamine Laminate

Main Features 1. Aging treatment: The steel used in our lamination machine was after aging treatment, that's make our material more uniform stress. High Speed Short Cycle Woodworking Hot Press Machine

Main Features 1. Aging treatment: The steel used in our lamination machine was after aging treatment, that's make our material more uniform stress. High Speed Short Cycle Woodworking Hot Press Machine Wuxi Qiangtong Machine Factory has built a solid reputation over 12 years of groundwork and over 150 units if QT lines are using by our honored customers from Iran, Turkey, Canada,Mexico, Venezuela,India, Egypt, Uzbekistan, Kazakhstan.,etc.

Wuxi Qiangtong Machine Factory has built a solid reputation over 12 years of groundwork and over 150 units if QT lines are using by our honored customers from Iran, Turkey, Canada,Mexico, Venezuela,India, Egypt, Uzbekistan, Kazakhstan.,etc.

Detailed Images

Detailed Images  Machine Parts Name: Belt conveyor loader The belt conveyor loader is used for sending the paper together with the raw board automatically.

Machine Parts Name: Belt conveyor loader The belt conveyor loader is used for sending the paper together with the raw board automatically.

Machine Parts Name: Vacuum pad unloader The vacuum pad unloader is for unloading the laminated board by vacuum pad instead of pushing by hand.

Machine Parts Name: Vacuum pad unloader The vacuum pad unloader is for unloading the laminated board by vacuum pad instead of pushing by hand.

Roller table

Roller table  Our Service Pre-Sales Service 1> Provide the free consultation of the equipment

Our Service Pre-Sales Service 1> Provide the free consultation of the equipment

Some parts in wooden case, some parts without package, which are all suitable for ocean transport. Related Products

Some parts in wooden case, some parts without package, which are all suitable for ocean transport. Related Products

Laminate floor hot press 91.8% Response Rate Multi layers door skin hot press 91.8% Response Rate Automatic laminate hot press line 91.8% Response Rate

Laminate floor hot press 91.8% Response Rate Multi layers door skin hot press 91.8% Response Rate Automatic laminate hot press line 91.8% Response Rate  Contact us if you need more details on Woodworking Hot Press Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cycle Woodworking Hot Press Machine、Short Cycle Woodworking Hot Press Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Woodworking Hot Press Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cycle Woodworking Hot Press Machine、Short Cycle Woodworking Hot Press Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.