Double sides MDF board melamine laminating machine Application The short cycle press line is for laminating melamine paper / phenolic film / veneer on particle board / MDF / HDF / plywood. The laminates could have all kinds of surface texture such as glossy, mirror, matt, suede, snow, woodgrain, and EIR board.

Semi-automatic and fully automatic model

We can make different solutions according to customers' requests, please tell me your idea or what functions you want, we will make most suitable project for you. Machine models

Model Size( ft ) | Nominal pressure (KN) | End panel size (mm) | Max pressure of work piece (kg/cm2) | Main oil cylinder (diameter x pcs) |

YX900 | 4x8 | 9000 | 1220 x 2440 | 30.2 | φ280 x 6 |

YX1200 | 4x8 | 12000 | 1220 x 2440 | 40.3 | φ320 x 6 |

YX1400 | 4x8 | 14000 | 1220 x 2440 | 47 | φ340 x 6 |

5x8 | 14000 | 1550 x 2440 | 37 | φ340 x 6 |

6x8 | 14000 | 1830 x 2440 | 31.3 | φ340 x 6 |

| YX1600

| 4x8 | 16000 | 1220 x 2440 | 30.2 | φ320 x 8 |

6x8 | 16000 | 1830 x 2440 | 35.8 | φ320 x 8 |

6x9 | 16000 | 1830 x 2750 | 31.7 | φ320 x 8 |

7x9 | 16000 | 2100 x 2750 | 27.7 | φ320 x 8 |

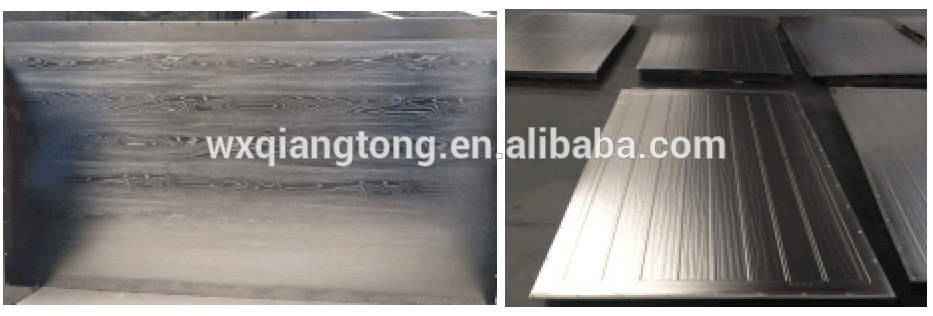

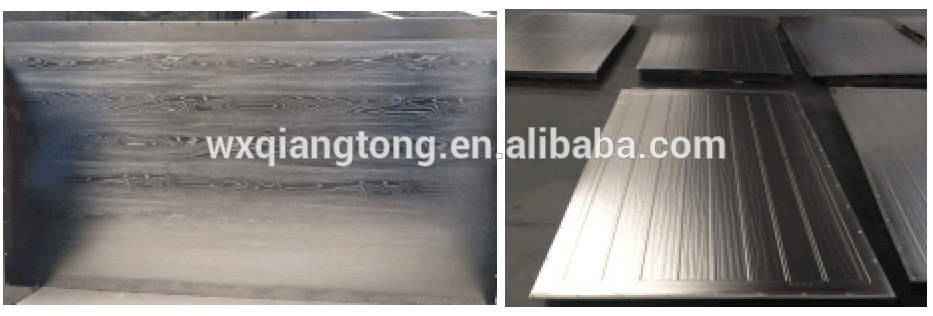

Necessary parts for press machine prodution S.S. chrome plates This stainless steel chrome plate is a necessary part for lamination, which is installed in the press machine for making different kinds of texture on the laminated board. The typical design is glossy, matt, suede, woodgrain etc.

Cushion Pad

Cushion PadThis is necessary part installed between

Hot Platen and the S.S. chrome plate for transferring the temperature and buffering the pressure to lead a uniform heat and pressure.

Temperature control unit

There are two ways to control the hot platen temperature, one is by single 3 way temperature control vale, and the other way is by a recycling system. Both of them can supply max. temperature 450 ℃ and the temperature accuracy is ±1 ℃. Single temperature control valve

Recycling temperature control model

Boiler

BoilerThe boiler is for supplying the hot oil to the hot press machine, this is supplied from the boiler factory, there are many kinds of boiler depends on different fuel, such as coal, natural gas, diesel, electric etc. Except the coal boiler, all the other types fuel boiler has two models, one is dis-assemble boiler which only has the main boiler and the separate oil tank and electrical cabinet, another is assemble boiler which combines all the system, the user doesn’t need to do any installation work, the supplier load as a whole complete unit.

Advantages 1. Control system: PLC control with connection to computer (Mitsubishi, Omron, Siemens optional), from infeed to storage, complete lamination offered.

2. We exported business since 2010 and have cooperated with a lot of honored customer in Iran, Turkey, Canada, Mexico, Venezuela, India, Egypt, Uzbekistan, Kazakhstan, South Africa, Russia, Vietnam etc.

3. CE certificate Any questions, please feel free to contact me!

Contact us if you need more details on Mdf Board Melamine Laminating Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Double Sides Laminating Machine、Wood Laminating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Short Cycle Hot Press Line > Melamine Laminate

Semi-automatic and fully automatic model

Semi-automatic and fully automatic model We can make different solutions according to customers' requests, please tell me your idea or what functions you want, we will make most suitable project for you. Machine models

We can make different solutions according to customers' requests, please tell me your idea or what functions you want, we will make most suitable project for you. Machine models  Cushion Pad

Cushion Pad Temperature control unit

Temperature control unit Recycling temperature control model

Recycling temperature control model  Boiler

Boiler Advantages 1. Control system: PLC control with connection to computer (Mitsubishi, Omron, Siemens optional), from infeed to storage, complete lamination offered.

Advantages 1. Control system: PLC control with connection to computer (Mitsubishi, Omron, Siemens optional), from infeed to storage, complete lamination offered.