Specifications Mainly for making paper 's dipping, sizing, drying and stacking. Suitable for furniture, floor paper and similar products.

Company The impregnation line is used for making impregnated paper which is for making laminates or pre-lamination of particle boards overlaying. UM Two-Step impregnation line: Suitable for 4-8 feet decor,shuttering,solid color,overlay and balance paper for furniture,flooring and HPL industries. Advantage: Longer service life of hot press plate,high transparency and lower cost compared with traditional progress. 1. Impregnation line adopts RS422 and RS485 technology and the realization of such a communication control with human-computer interface (touch screen) , PLC and frequency converter as a substitute of the traditional panel control, which have greatly improved the digitization standard. 2 It has industrial standard modularized design, handy human-computer dialog and rich information reminder in english. 3 The high precision gauging roller ensures the gluing precision and surface quality of the impregnator. 4 The high precision gravure roller with precision scrubber secures the preciseness of glue coating. 5 The advanced and reliable tension control system works effectively in controlling the strain of the paper tape operation. 6 Both the transmission roller and the hot-air blower come with high efficient energy-saving inverter control to reach low energy consumption, synchronous linear stability and low paper breakage. 7 The double photoelectric synchronous motor controls and adjusts deviation to have the deviation adjustment stability and the stead operation of paper. 8 The paper cutter is available with the coding technology of preciseness and accurateness and being capable of setting the cutting length at will. 9 The temperature of the drying chamber comes with PID high-precise control and the exact-accurate temperature control. 10 The ratio and systematic parameters can be regulated online synchronously. 11 It is possible to inquire and make the statistics of the output on the daily, monthly and yearly bases. Finished products--impregnated paper:

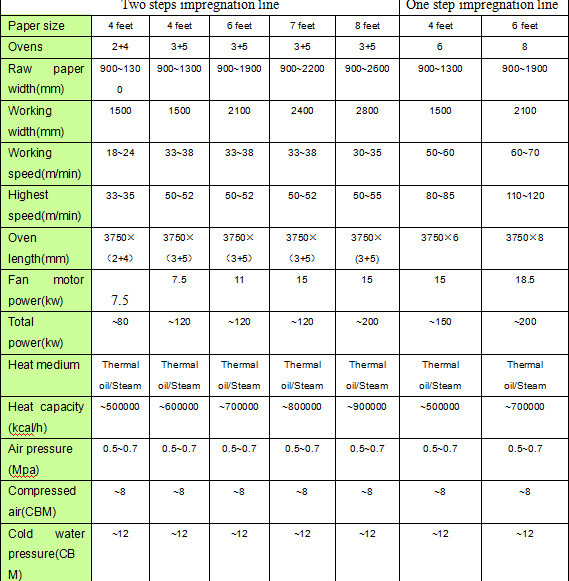

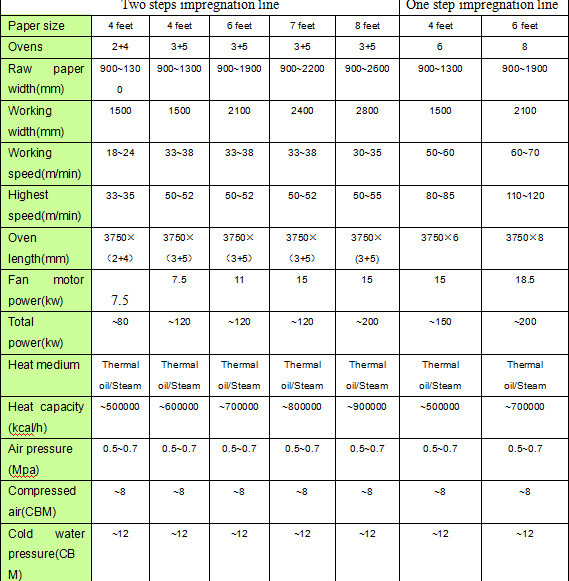

specification

Photos for showing

Packaging & Shipping We have the full experience on packaging,because every year,we will export more than 30 sets machine to different country,our work will finish the work without any damage to the machine body,and we also have many portection ways to protect the machine from rain and sea water .

Contact me ! Maksim Wang Cell:0086-13606178633

Contact us if you need more details on

Paper Impregnation Line/ Plant. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Kraft Paper

Impregnation Line、Hpl Producing Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Paper Impregnation Line

specification

specification  Photos for showing

Photos for showing

Packaging & Shipping We have the full experience on packaging,because every year,we will export more than 30 sets machine to different country,our work will finish the work without any damage to the machine body,and we also have many portection ways to protect the machine from rain and sea water .

Packaging & Shipping We have the full experience on packaging,because every year,we will export more than 30 sets machine to different country,our work will finish the work without any damage to the machine body,and we also have many portection ways to protect the machine from rain and sea water .

Contact me ! Maksim Wang Cell:0086-13606178633

Contact me ! Maksim Wang Cell:0086-13606178633